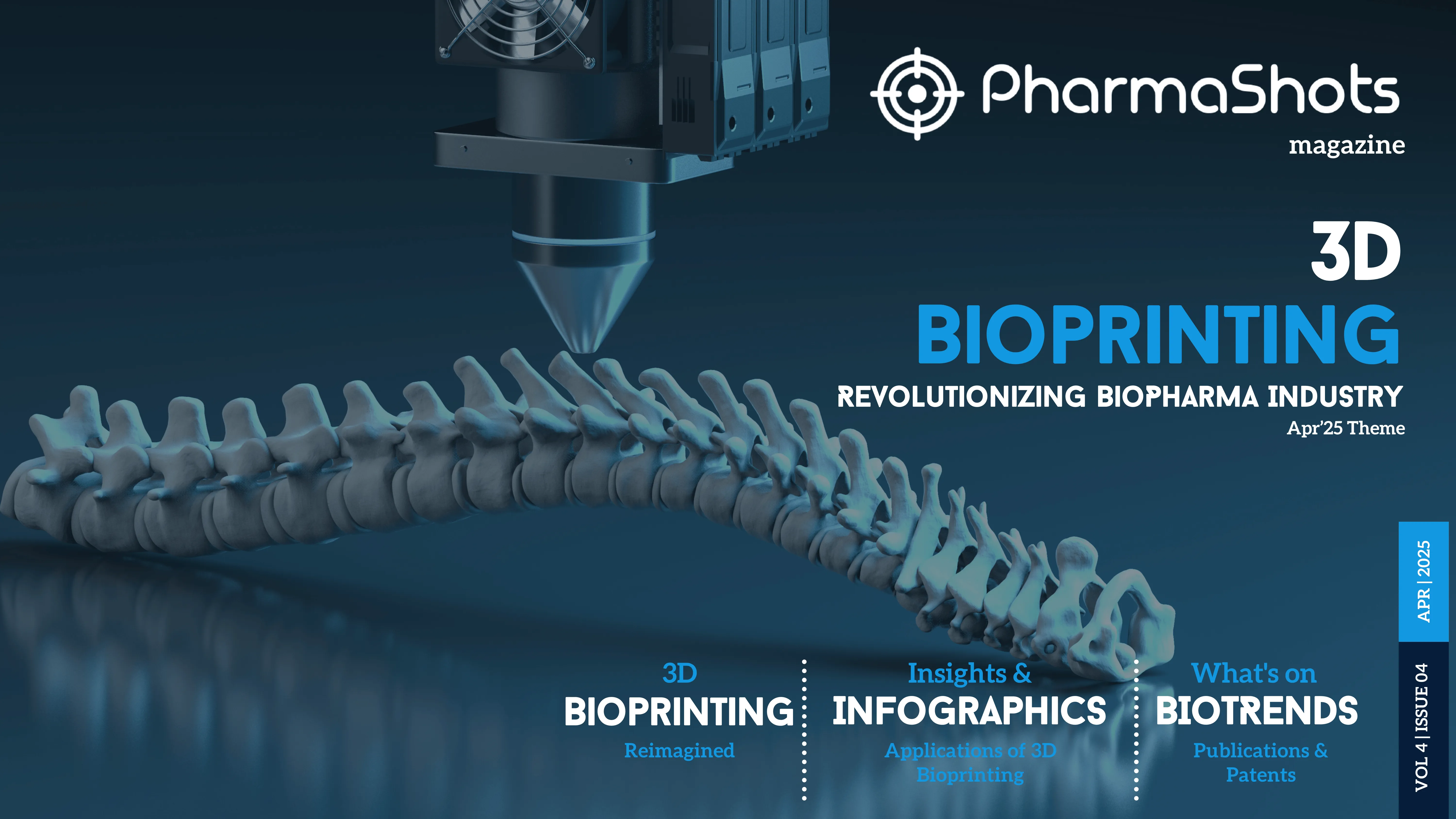

3D Bioprinting Represents a Huge Leap in the Pharmaceutical Industry

Three-dimensional technology has been an integral part of the pharmaceutical industry for many years. The medical fraternity has witnessed the clinical benefits of 3D technology such as printed anatomical prostheses, heart valves, biological tissues, hearing aids, and much more. The global 3D printed drugs market was valued at US$ 29 million in 2019 and is expected to grow at a CAGR of 9.1% from 2020 to 2027. The factors driving the 3D printed drugs market growth include the increased delivery of personalized medicines, extensive research, and development activities. Its application in the manufacturing of drugs is very attractive since it caters to personalized medicine. With extensive research and progress in cell biology, nanotechnology, and material sciences, a new concept has surfaced, 3D Bioprinting.

What is 3D Bioprinting?

3D bioprinting, a novel technology, is basically a manufacturing process to generate tissue-like structures that behave as natural tissues. The simplest bio-printed tissue is a single layer, like skin. The ingredients are 'biomaterials' i.e. cells and growth factors. A key difference between 3D printing and 3D bioprinting is that a living cell suspension is used in the case of bioprinting rather than thermoplastic, used in the conventional 3D printing method. The cells are usually extracted from the patient or if not possible, adult stem cells are used which are then cultured carefully and converted to 'bio-ink' which by its name, prints the desired tissue or organ.

How is 3D Bioprinting done?

- 3D Imaging: A standard imaging (CT or MRI scan) is done to get the exact dimensions of the tissue/organ.

- 3D Modeling: A mode / blueprint of the organ/tissue is created by using AutoCAD software to avoid the transfer of defects.

- Bioink Preparation: it is the combination of the patient`s living cells, compatible basin (gelatin, collagen, etc.) and cell growth factors based.

- Printing: Deposition of the prepared bioink Layer-by-layer on the AutoCAD design.

- Solidification: Solidifying the structure may be aided by using specific chemicals, UV light, or heat.

Why 3D Bioprint?

The main objective of bioprinting would be to provide an alternative to autologous and allogeneic tissue implants. In the coming time, it will gradually replace animal testing and thereby speed-up the drug development process. The long term objective is to deliver personalized tissues/organ made from the patient`s own cells. It would hypothetically have fewer rejection rates. Who would be the owner of that organ? This could be an ethical challenge to ponder upon.

A small, yet powerful step would be the creation of tissue components for the heart, liver, pancreas, and other vital organs. In the future, 3D bioprinting will make organs widely available to those who need them, instead of being on a transplant list for many years.

Advantages

- Reduce research and development costs by replacing animal testing.

- Testing a drug`s efficacy on a fully bioprinted organ/tissue before invitro or human study.

- It could solve the current organ transplant waiting list problem.

- Customized training materials could be deployed in medical colleges to help train students and physicians.

- Accurate cell distribution

- High-resolution cell deposition

- Scalability

Challenges

- There is limited availability of good quality data. This could be due to a lack of interest by the pharmaceutical development researchers, high costs incurred upon the company, and less information on bioinks.

- Strict regulations

- Cost-estimation is difficult

- Reimbursements

- Tissue-specific bioink

- Improve current 3D Bioprinters to enhance resolution and detailing

- Large scale production

The future of 3D bioprinting is bright for the pharmaceutical industry due to the trend of more personalized medical treatments. The increasing demand for customized therapeutics will help the 3D bioprinting industry is emerging. It would become possible to 3D print tissues and even organs, which would make a lot of lives happier and healthier. In the coming years, 3D bioprinting could even help repair a damaged liver. A bioprinted liver patch created from the patient`s own liver cells could be the solution. Finally, 3D bioprinting represents a huge leap forward from animal testing and cell culture.

It is time for India's nascent 3D bioprinting industry to step up

References:

- Samiei N. Recent trends on applications of 3D printing technology on the design and manufacture of pharmaceutical oral formulation: a mini review. Beni-Suef University Journal of Basic and Applied Sciences. 2020 Dec;9:1-2.

- Murphy SV, Atala A. 3D bioprinting of tissues and organs. Nature biotechnology. 2014 Aug;32(8):773-85.

- Worldwide Industry for 3D Printed Drugs to 2027 - Rising Awareness About 3D Printing Technology Presents Opportunities

- 3D Printing & Bioprinting in Pharmaceutical Manufacturing

Image Source: NCBI-NIH

Related Post: ViewPoints Article: Digital Biomarkers

Parshuram Nivrutti, M.Pharm currently serves as Assistant Manager, Medical Affairs Executive in IntelliMed Healthcare Solutions.